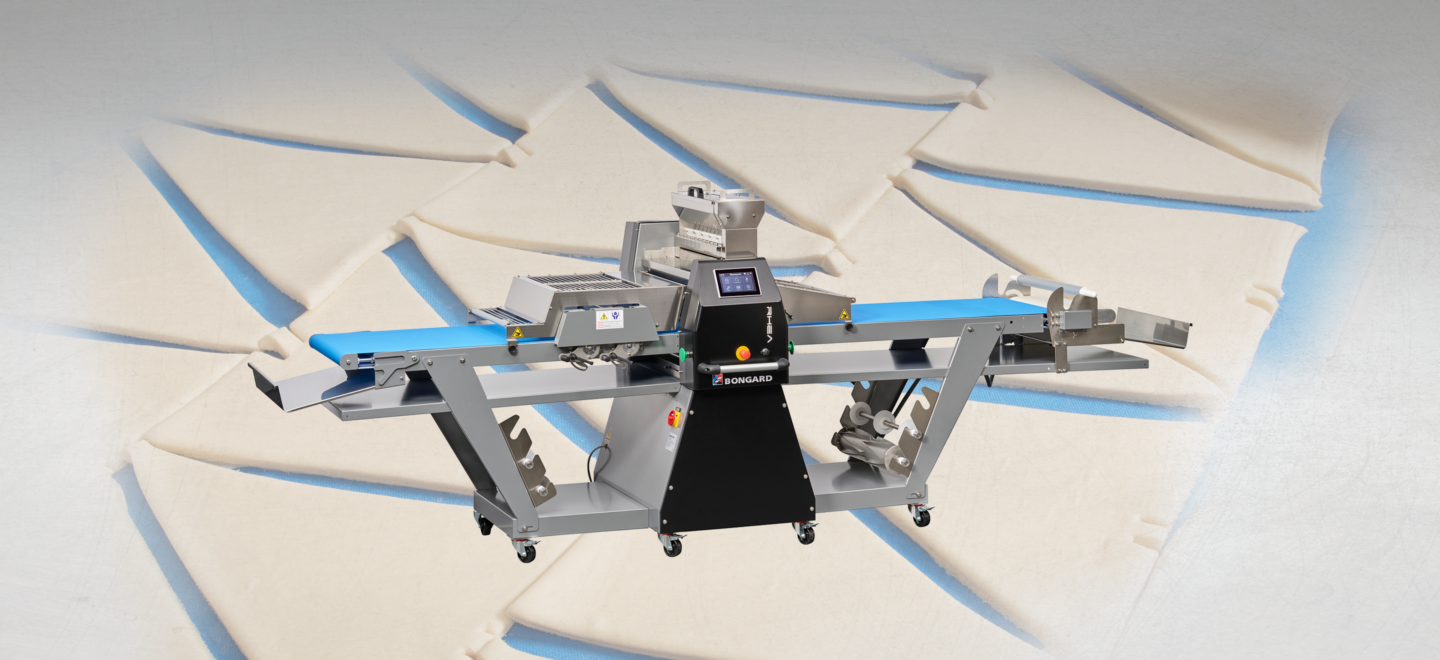

Des solutions adaptées à vos besoins

Paneotrad®, un pari gagnant pour qui sait oser | Gilles et Valérie Vaïano | Ollioules

Ils témoignent

« Avec Paneotrad®, il est primordial d’être rigoureux et régulier au niveau de la température des pâtes et des temps de pointage. Une fois cela maîtrisé, le résultat est magnifique ! »

Témoignage complet dans le dernier Forum'Mag.

Bongard dans le monde

115 salariés conçoivent les machines 350 vendeurs et techniciens en France 450 vendeurs et techniciens dans le monde

Notre actualité

Suivez toute l’actualité Bongard sur les réseaux :

Facebook YouTube LinkedIn Instagram